There are very few car makers that do not use robots in their assembly line. Robots are efficient and they can do repetitive tasks with high-degree of accuracy and little to no risk of errors. Mercedes-Benz has been using robots to make cars, but recently the company announced that those robots would be replaced with real people due to difficulties to make custom cars.

Many car makers are trying to replace people with robot to achieve better efficiency and lower production cost, but Mercedes does not want to use only robots in the assembly line. There are probably some robots here and there, but people will take over major parts in the manufacturing processes. One of the main reasons is that robots cannot handle high degree of individualizations and numerous variants that Mercedes offers particularly the S-Class options. The number of available options for S-Class is dizzying. If you want to buy a brand new S-Class now, you get to choose from four different caps for tire valves, carbon fiber trim, or even temperature-controlled cup holders among others. With high demand of flexibility and adaptability to buyers’ tastes of their vehicles, robots are easily outperformed by people.

Just last week, the International Federation of Robotics reported that there will be about 1.3 million industrial robots entering factories by 2018. The federation also suggests that automotive industry is the largest user of industrial robots. And what Mercedes just did may not deny the report, but it certainly brought a relief not only to potential employees but also car enthusiasts. Robots are reliable, precise, and probably inexpensive to maintain, but human intervention on manufacturing process ensures that every car meets customers’ needs for personalization or customization.

Mercedes also plans to add 30 more different models by the end of 2020, including at least 10 new styles with even more customization options. More models with more options lead to more personalization; this is something that robots cannot handle. The company also tries to reduce the hours needed to produce a car from 61 hours in 2005 to 30 hours only.

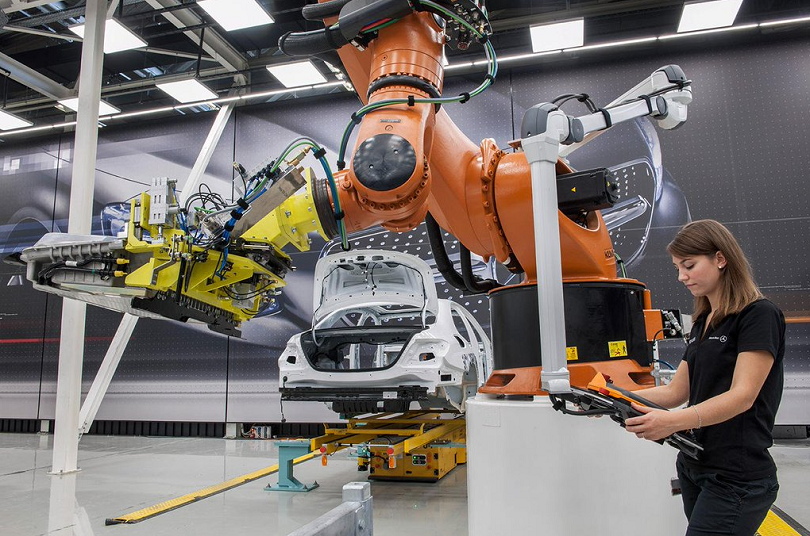

Lightweight machines will still be used anyway. But it means that people are the actual assembly workers assisted with robots, not the other way around. There is an increasing competition between luxury car makers, and customization is one of the most important keys to stay ahead in the market. Skilled professionals can change the entire production line during a weekend, while robots take weeks to reprogram.

Mercedes-Benz is not the only company to implement the new method in assembly line because two other German-based car makers, Audi and BMW, are also testing robots with enough intelligent and safety features to create safe working environment between them and human.

Leave A Comment